Save time and money with planning-first shipping optimization.

CONTACT USTraditional methods—such as emailing carriers, double-checking spreadsheets, and manually updating data—often result in missed details, extra costs, and limited capability.

When shipments are late, or inventory levels are miscalculated, everyone immediately feels the impact. These issues can quickly accumulate, diminishing efficiency and client satisfaction.

Fortunately, logistics automation offers a way forward. By automating repetitive tasks, monitoring operations in real-time, and collecting better-quality data, organizations can make decisions more quickly, reduce the risk of human error, and drive down operational expenses.

This article explores how automation can overhaul supply chain management. It provides strategies for cost reduction, practical use cases, and insights into how Planimatik freight control, through innovative planning tools, supports these transformations.

Key takeaways

-

Understand the core meaning of logistics automation and how it applies to different parts of the supply chain.

-

Learn how automating tasks reduces administrative overhead, prevents costly errors, and optimizes resource allocation.

-

Discover technologies driving automation, including warehouse and transportation systems, AI, IoT, and cloud computing.

-

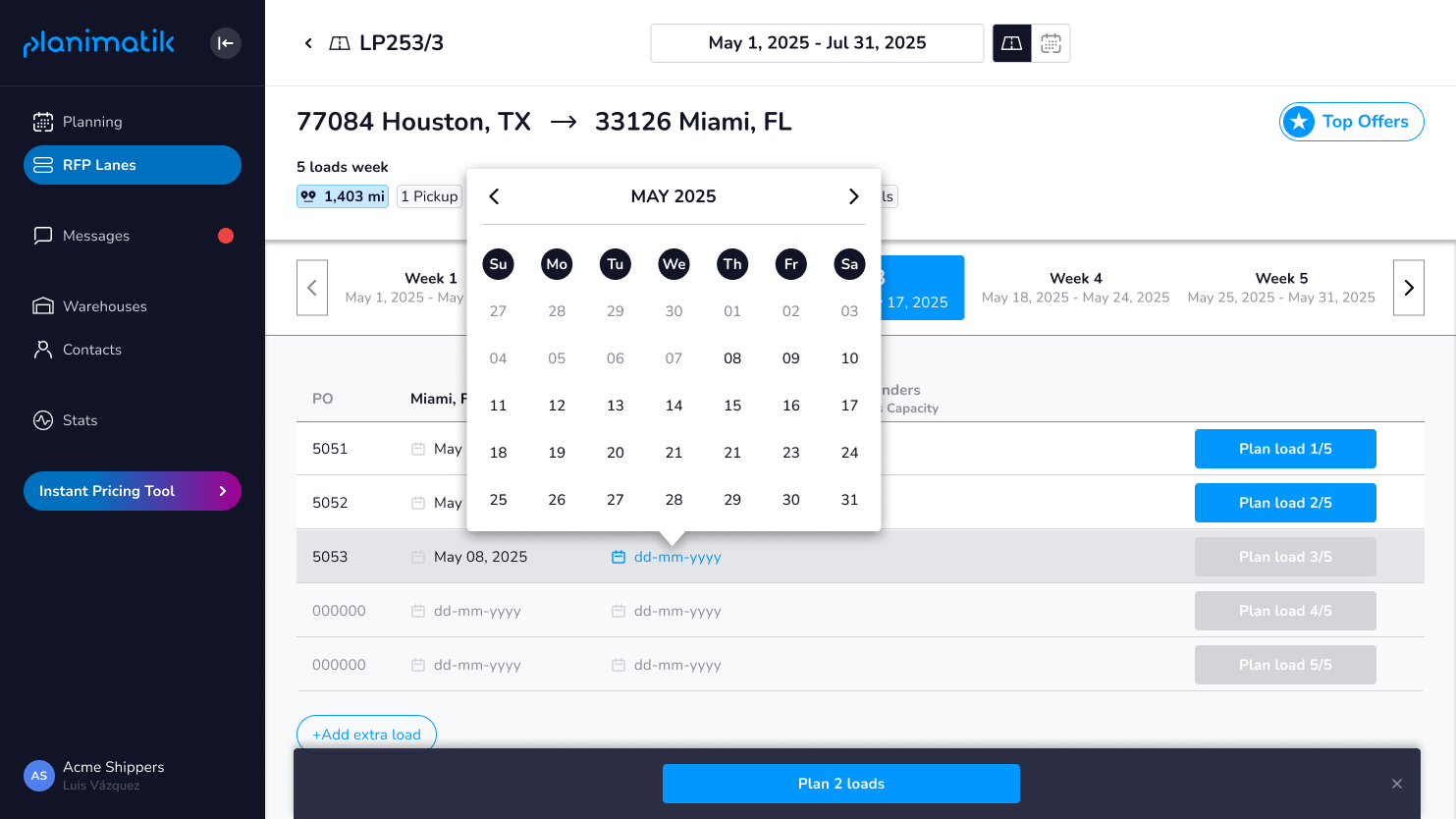

Gain insight into how Planimatik’s Automated Planning and Stats features tackle pain points such as data overload, complex coordination, and cost control.

-

Explore potential implementation challenges—like high initial costs or system integration—and discover strategies to address them.

What is Logistics Automation?

Logistics automation involves using technology and software solutions to manage and optimize supply chain tasks, from order processing and inventory management to shipping and warehousing. In practice, this can mean automated data entry, real-time shipment tracking, or generating precise forecasts for future demand.

By integrating automated processes into everyday logistics operations, businesses can minimize manual intervention, decrease errors, and ensure higher levels of consistency.

This concept stretches across every area of the supply chain:

-

Order Processing: Automated systems handle incoming orders, check inventory availability, and process documentation without constant manual oversight.

-

Inventory Management: Real-time visibility helps keep stock at optimal levels, preventing oversupply and stockouts.

-

Transportation Management: Scheduling shipments, choosing carriers, and monitoring transit times can all be automated for a smoother flow of goods.

-

Warehouse Operations: Tools such as automated guided vehicles and robotics aid in picking, packing, and sorting items.

To see how you can upgrade or refine your logistics operations, check out our detailed guide on optimizing your logistics processes.

How Does Logistics Automation Benefit Businesses?

- Efficiency Gains: Automation frees staff from repetitive tasks, enabling them to tackle more strategic issues. This can increase throughput, reduce administrative burdens, and deliver faster order fulfillment.

- Cost Reduction: Fewer mistakes in documentation or billing, better inventory handling, and reduced labor costs are just some ways that automation keeps the budget in check. Explore our guide on reducing logistics without losing service quality for further learning.

- Improved Accuracy: Data entry errors and inconsistent updates often result in shipment delays or inventory mismatches. By relying on software-driven workflows, logistics managers can see more precise data and share consistent updates with their teams and customers.

- Enhanced Customer Service: When deliveries run on schedule and stock levels accurately reflect demand, end customers receive timely, reliable service. This can strengthen your company’s reputation and foster brand loyalty.

- Competitive Advantage: Staying on top of new technology trends in logistics can help a business outpace competitors. Rapid order fulfillment, real-time inventory checks, and streamlined routing build trust with clients while standing out in a crowded market. For the latest trends, see our article on technology in logistics for streamlined operations.

How Can Logistics Automation Reduce Operational Costs?

Cost pressures are a constant concern for logistics managers. By using automated platforms, companies often see reductions in waste, labor costs, and delays. Below are specific ways logistics automation leads to greater cost efficiency:

- Eliminating Repetitive Tasks: Manual tasks—like inputting shipment details—consume valuable time and are prone to mistakes. Automated processes reduce the need for staff to repeat data entry across multiple platforms..

- Reducing Shipping Errors: Automation ensures that shipping labels are correct and inventory counts are in sync. Fewer errors translate directly to savings, as returns, re-shipments, and extra communication add up quickly.

- Improving Forecasting: Better data analysis and predictive models allow logistics managers to effectively balance stock levels, lowering warehousing expenses and preventing stockouts.

- Optimizing Resource Allocation: Automated systems can coordinate routes and schedules, finding the best use of vehicles and personnel. Tools such as Planimatik’s Automated request for proposal (RFP) management feature can apply recurring criteria, like pickup and delivery times, to reduce wasted capacity.

- Preventing Data Overload: Having a platform that collects, analyzes, and displays data in simple dashboards—like Planimatik’s Stats—ensures logistics managers aren’t overwhelmed. Clear visualization means faster, more accurate decision-making and reduced guesswork.

These cost-saving strategies become more apparent when tested in real-world environments. For instance, an ITS company user of Planimatik’s solutions found a 20% decrease in overall logistics costs after implementation, as detailed in our case study.

"Thanks to Planimatik, we've unlocked many advantages, optimizing our operations and achieving significant cost savings, time reduction, and efficient decision-making. This transformative solution positions us for success in the competitive logistics landscape." - Catalina Machado, ITS CEO.

Common Technologies Used in Logistics Automation

Modern supply chains are too complex for manual oversight alone, particularly if you’re planning hundreds or thousands of weekly shipments. Hours of administrative work can pile up, leaving little time for strategic planning or data analysis. This is where advanced logistics automation tools excel.

Below is an overview of the core technologies driving more efficient and adaptable supply chains

Warehouse Management Systems (WMS) and Transportation Management Systems (TMS)

WMS tools help companies track inventory, optimize storage locations, and streamline picking and packing tasks. TMS solutions focus on routing, dispatching carriers, and managing billing or freight documents.

WMS and TMS form the backbone of many automated logistics operations, improving workflows from receiving an order to its final delivery.

Planimatik’s Digital Freight Platform integrates seamlessly with these systems to simplify day-to-day processes. Planimatik’s Automated Planning eliminates that extra work by automatically applying your predefined parameters, ensuring consistent scheduling without hours of repetitive data entry.

By pairing WMS/TMS data with Planimatik’s intuitive dashboards—like the Stats view—logistics managers can visualize their entire operation in real time, spotting cost patterns and performance trends that might go unnoticed. For more on quick TMS rollouts, see our guide to TMS implementation.

Robotics and Autonomous Vehicles (AGVs)

AGVs are handling repetitive or physically strenuous tasks. Robots handle picking, packing, and sorting accurately, reducing labor-intensive workloads. AGVs, meanwhile, transport goods across facilities, relying on sensor-guided routes that minimize collisions and delays.

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML continuously transform how logistics decisions are made. These algorithms can flag inefficiencies or predict potential bottlenecks by processing shipment data, traffic patterns, and historical performance.

They generate cost-saving route suggestions and improve over time, learning from new information or exceptions.

For logistics teams with fluctuating demand—like those scaling up for holiday surges—AI helps ensure each decision is grounded in data.

Internet of Things (IoT)

The global IoT in warehouse management market is projected to grow from $12.13 billion in 2023 to $28.79 billion by 2030, highlighting its growing significance in logistics operations.

IoT devices connect physical assets—like pallets, trailers, and containers—to digital platforms for real-time monitoring. Sensors may track temperature, vibration, or geo-location, delivering immediate alerts if goods deviate from set conditions. This increased visibility can prevent spoilage and losses, particularly in cold-chain or high-value shipments.

Blockchain Technology

The blockchain market is expected to grow to nearly 1,000 trillion U.S. dollars by 2032, and Gartner forecasts $3.1 trillion in new business value by 2030. Blockchain brings unprecedented transparency and security to logistics transactions.

By creating a shared, tamper-proof record, all parties—suppliers, carriers, customs agencies—can trace items from origin to final destination. This is especially valuable in regulated industries like pharmaceuticals and food, where authenticity and safety are paramount.

Cloud Computing and Big Data

The cloud underpins much of today’s logistics automation by allowing companies to store, share, and analyze data in real time, regardless of the user’s location. Big data techniques further enrich this process, discovering trends or correlations that might remain hidden in static spreadsheets.

Planimatik leverages a fully cloud-based approach, so everyone involved—planners, carriers, and warehouse staff—can update and access the system from anywhere.

Automated analytics scan massive data sets to identify unexpected cost overruns, route inefficiencies, or recurring process delays. This robust data environment allows for more collaborative decision-making and speeds up reaction times if demand suddenly fluctuates.

Overcoming Potential Challenges when Implementing Logistics Automation

Automation projects can introduce uncertainties. Below are common obstacles and how Planimatik helps address them:

High Initial Investment Cost

Challenge: Deploying robotics, AI platforms, or new software often requires substantial upfront spending. For smaller businesses, this can be daunting.

Solution

- Planimatik offers subscription-based pricing, eliminating the need for significant capital investments.

- Implementation is surprisingly quick—under 2 hours in many cases—allowing businesses to start benefiting from automation immediately, without waiting months for complex installations.

Integration with Existing Systems

Challenge: Legacy systems may not be ready to share data with new platforms, creating compatibility issues and duplicating workflows.

Solution

- Planimatik’s digital freight platform is built with open architecture, which allows integration with carriers, warehouse management systems, and third-party tools.

- Detailed documentation and dedicated support help shorten the learning curve and reduce the risk of data silos.

Cybersecurity Threats

Challenge: More connected systems mean broader vulnerabilities to hacking, malware, or data breaches.

Solution

- Planimatik follows industry best practices for data protection. This includes secure data transfer protocols, role-based access control, and regular security audits.

- Logistics managers should also adopt common-sense measures, such as strong passwords and staff training on phishing risks.

Resistance to Change in Workforce

Challenge: Employees may hesitate to transition from manual procedures to new technologies, fearing job displacement or complexity.

Solution:

- Planimatik is designed with simplicity in mind, featuring an intuitive user interface that doesn’t require extensive training.

- Managers can encourage teams to embrace new software by highlighting how automation relieves staff of tedious tasks.

Planimatik: Helping You Navigate the Future of Logistics Automation

Embracing logistics automation can be the difference between lagging competitors and achieving higher service quality. Automated processes reduce manual errors, prevent cost overruns, and help managers focus on long-term improvements instead of daily firefighting.

Modern logistics rely on a host of technologies to stay competitive. Yet many solutions overlook the crucial element of planning for repetitive routes and complicated schedules, leaving logistics managers to handle endless manual tasks or complex spreadsheets.

Planimatik stands out as an ally for logistics managers moving into automated workflows. Its Automated planning feature applies recurring parameters—such as pick-up times and lane preferences—across shipments, eliminating the tediousness of manual scheduling. Its Stats dashboard visualizes carrier performance, average costs, and trailer usage, letting you interpret data at a glance and act decisively.

To see how Planimatik can modernize your supply chain and help you leverage logistics automation at scale, book a free demo. This is your opportunity to discover how advanced planning features, real-time data analytics, and a user-friendly interface can revolutionize your operations.

.png)

.png)

.png)

.png)

.png)

READ MORE

READ MORE

.png?width=464&height=512&name=13-cta-img-01%20(2).png)